Fúinn

Diverse, High-Quality Products for Critical Industries

We specialize in producing premium stainless steel mesh baskets, sterilization baskets, drying racks, and industrial containers. Our products cater to diverse needs, including parts cleaning and small item handling, and are trusted by leading clients in pharmaceutical, defense, automotive, aerospace, and food processing industries—consistently meeting their rigorous quality standards.

Advanced Manufacturing Capabilities for Precision and Efficiency

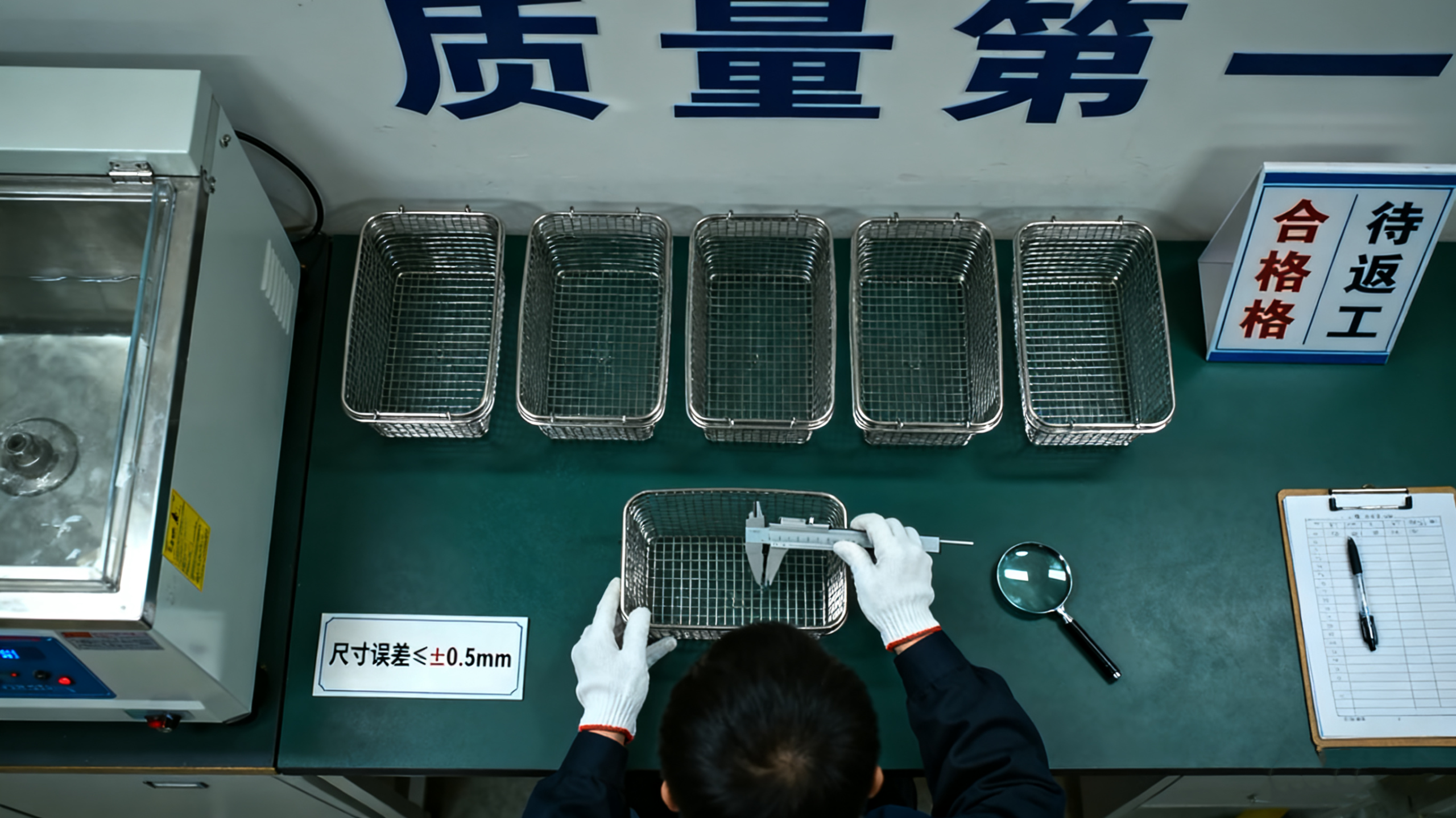

Equipped with state-of-the-art machinery such as CNC machines and pulse TIG welders, we leverage precision cutting and bending technologies to maintain tight dimensional tolerances (±0.5 mm). Our advanced welding processes ensure strong, clean, and aesthetically pleasing welds. Key product lines include versatile equipment loading baskets and food-grade stainless steel mesh baskets, all manufactured to meet the exact specifications of our clients.

Innovative Design and Timely Delivery for Your Business Needs

Our experienced engineering team uses advanced virtual testing software (including Autodesk) to validate basket designs thoroughly, eliminating time-consuming prototype iterations and saving you time and money. By harnessing the speed, efficiency, and precision of automated manufacturing, we rapidly deliver high-quality wire baskets with superior consistency—ensuring you get exactly what you need, when you need it.

Company Profile:

stainless steel mesh baskets, sterilization baskets, drying racks, and industrial containers. If you require wire mesh baskets for parts cleaning or handling small items, Feier is your ideal partner.

We manufacture thousands of custom baskets and racks each week for demanding clients across various industries, including pharmaceutical, defense, automotive, aerospace, and food processing, consistently meeting their rigorous standards.

Our facility is equipped with advanced machinery such as CNC machines and pulse TIG welders. By employing precision CNC cutting and bending technologies, we maintain tight dimensional tolerances within ±0.5 mm.

Production Capacity:

Our experienced engineering team utilizes advanced virtual testing software, including Autodesk, to validate basket designs thoroughly. This approach eliminates the time-consuming cycle of building multiple non-functional prototypes, saving you both time and money.

Leveraging the speed, efficiency, and precision of our automated manufacturing solutions, we rapidly deliver high-quality wire baskets with superior consistency. We are equipped to produce exactly what you need and ensure timely delivery.

Honors and Certificates: